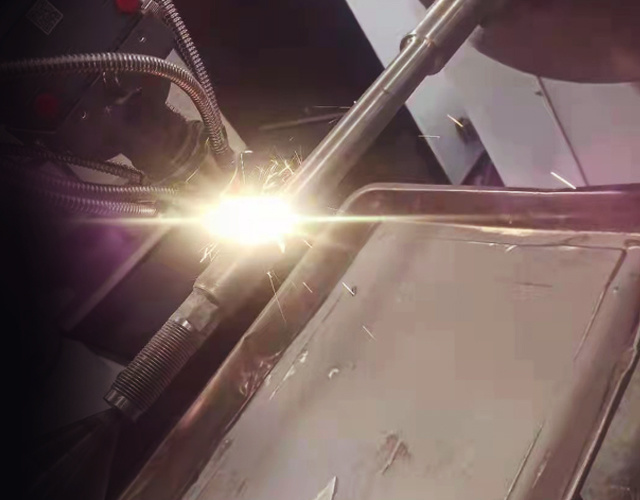

Applications of high-speed laser cladding machines in industry

High-speed laser cladding machine Mainly used for rapid preparation of corrosion-resistant, wear-resistant, or other special performance coatings on the surfaces of parts such as shafts and discs, such as oil cylinders, columns, rollers, spindles, and brake pads. Guide vane laser cladding machines are widely used in coal mining, transportation, steelmaking, offshore platforms, drilling and mining, and heavy machinery industries. It is used not only for manufacturing new parts but also for surface maintenance and process manufacturing of in-service parts.

Guide vane laser cladding machine application cases:

Corrosion-resistant, wear-resistant, and oxidation-resistant coatings: columns, shafts, rollers, etc.

Thin-walled, high-aspect ratio, and other parts that are easily deformed by heat.

Large-diameter heavy parts

Functional coatings with different roughness

Local damage repair

Guide vane laser cladding machine Mainly used for preparing wear-resistant and corrosion-resistant coatings or performing rapid laser repair on the inner holes and inner walls of parts. With different optical systems, blind holes at the ends of pipes can also be processed with 45° inclined incident laser and powder. Or the inner wall optical head can be rotated by a motor for vertical cladding processing of heavy parts or parts that are difficult to rotate; at the same time, it can also be used for laser repair and welding of narrow and confined parts. It has a large application demand in many industrial fields such as coal machinery, drilling, energy, heavy machinery, and aerospace.

Guide vane laser cladding machine application cases:

Preparation of corrosion-resistant and wear-resistant coatings: oil cylinders, bearing pairs, valves, conveying pipelines, etc.

Figure-8 injection mold

Blind hole parts

Small diameter parts

Extra-long parts

Heavy optical head rotating vertical cladding

Guide vane laser cladding machine - Laser repair is based on laser cladding technology, which quickly repairs surface and internal damage to parts, improves the service life of parts, and reduces production and maintenance costs. Processing errors, surface wear, casting defects, and damage during use can be restored and improved through laser repair. Molds, blades, rollers, and gear parts usually have a large number of repair requirements and will be applied to many industries such as aviation, transportation, molds, agricultural machinery, drilling and mining, and coal mining.

Guide vane laser cladding machine Application Cases:

Local defect repair: gears, molds, housings, blades, shafts, and joint parts, etc.

End face defect remanufacturing: cutting teeth, tooth tips, etc.

Cladding and repair of parts disks and mounting surfaces

Threaded parts

Related Information

RELATED INFORMATION

2022-08-26 10:09

2022-08-16 15:13

2022-08-08 10:10

Leave a message

MESSAGE CONSULTATION