How are the two applications of hydraulic rod laser cladding equipment technology implemented?

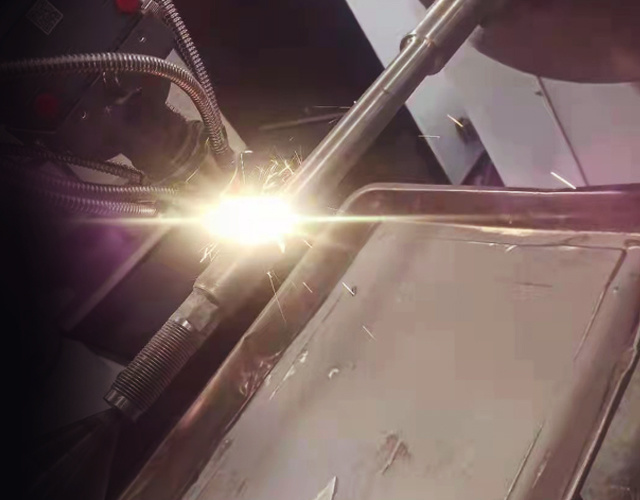

Hydraulic rod laser cladding equipment The rise of this technology utilizes a high-energy density laser beam to clad materials with special properties onto a substrate material, melting and fusing them to form a clad layer with a completely different alloy composition and properties than the substrate.

Hydraulic rod laser cladding equipment

Compared with other surface treatment technologies, laser cladding technology of hydraulic rod laser cladding equipment has the characteristics of wide application range, strong practicality, and flexible application. The laser cladding surface can be designed into surface layers with different properties such as wear resistance, corrosion resistance, and oxidation resistance according to the requirements of the part surface, forming a coating with metallurgical bonding and dense structure to the substrate, thus greatly improving the service performance of the specific working surface of the part and the service life of the entire workpiece. However, during the laser cladding process, temperature differences during the cooling stage easily lead to cracking of the coating due to stress, which is commonly known as cold cracking.

1. Generally, the reference is the spray welding process. After preheating the substrate, laser cladding is performed, which successfully reduces the temperature difference and greatly reduces the risk of coating cracking. However, if the preheating temperature is not precisely controlled, overheating can still cause substrate deformation and affect the overall accuracy of the workpiece. Therefore, adding a transition layer process to eliminate stress and reduce the risk of coating cracking is also beneficial.

2. In addition, it is possible that the non-metallic components of the alloy powder do not have time to float up and melt in the molten pool, so they are trapped among other melted components during the cooling stage, leading to slag inclusions and so-called hot cracks.

3. There are also mechanical cracks during post-processing, which are caused by excessive force applied to the brittle and hard parts of the coating structure during cutting, leading to structural fracture and coating cracking. The only solution is to reduce the cutting force.

In summary, it is necessary to change the alloy powder or increase the cladding time to create more floating and melting time for the non-metallic components.

In addition, the modern petrochemical industry adopts a continuous large-scale production model, and the supply and demand relationship between upstream and downstream equipment is closely related. The production stability of each equipment will directly affect the stability of the production line. Due to the long-term operation of mechanical equipment in harsh environments, corrosion and wear of parts are easy to occur, which puts high demands on the equipment's reliability and integrity.

Typical failure-prone parts in the petrochemical industry include impellers, disks, etc., these parts all use Hydraulic rod laser cladding equipment cladding technology for repair, and the size of the journal can be restored without preheating the workpiece. In addition, the subsequent processing amount is small, and metallurgical cracks are not easily produced, and the hardness of the repaired parts is increased. Not only is the maintenance cost reduced, but more importantly, the maintenance time is shortened, solving the problem of rapid maintenance required for the continuous operation of large-scale petrochemical equipment sets.

In addition, the use of ultra-wear-resistant and corrosion-resistant alloy surfacing for key parts can greatly improve the service life, and the surface of the parts will not deform; laser cladding on the surface of the mold can not only improve the mold strength but also reduce the manufacturing cost and shorten the manufacturing cycle.

For crankshaft repair, if plasma spraying is used for repair, the bonding strength between the coating and the substrate is insufficient, which may affect the safe operation of the equipment after reinstallation. However, surfacing is difficult to guarantee the wear resistance of the repair layer and the absence of cracks in the substrate. In view of these situations, Hydraulic rod laser cladding equipment has become a superior choice for repair.

Related Information

RELATED INFORMATION

2022-08-26 10:09

2022-08-16 15:13

2022-08-08 10:10

Leave a message

MESSAGE CONSULTATION