Application of high-speed laser cladding machine in aerospace manufacturing

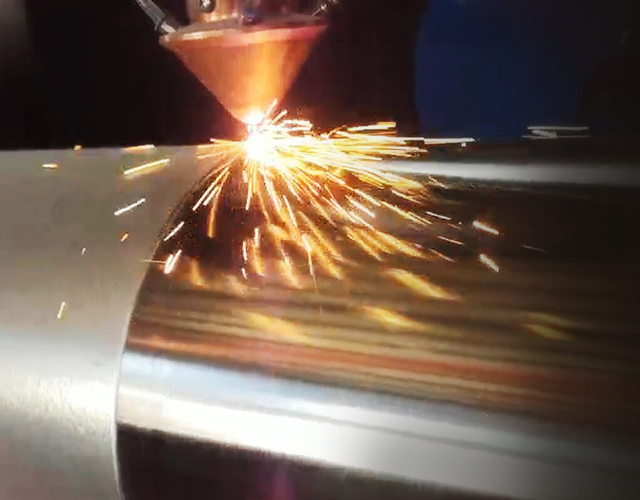

High-speed laser cladding machine It can use different filler methods to place coating materials on the surface of the substrate. After laser irradiation, it can simultaneously melt the thin layer of the substrate itself. After a short time of solidification, it can form a surface layer with low dilution and good bonding with the substrate material, thereby improving the corrosion resistance, wear resistance, oxidation resistance, heat resistance, and electrical properties of the parts. Using a guide vane laser cladding machine, not only can the purpose of repairing and modifying the material substrate be achieved, but it can also meet the requirements of the mechanical parts for material surface performance and save a lot of raw materials. Next, I will talk to you about the application of the guide vane laser cladding machine in the aerospace manufacturing field.

High-speed laser cladding machine Its cooling speed is quite fast, which is a rapid solidification process. Therefore, using this equipment, it is very easy to obtain crystalline structures or non-crystalline and non-steady-state structures that cannot be obtained by equilibrium state. Moreover, the dilution rate of the coating is very low, and it can be combined with the substrate material in the form of interfacial diffusion. By adjusting the mechanism and process parameters in the equipment, a coating with a low dilution rate can be obtained, and the composition and dilution rate of the coating can be controlled.

Its application in the aerospace field results in small heat input and distortion, and can be reduced to within the assembly tolerance of aerospace equipment parts. Moreover, there is almost no limitation on the selection of powder, especially for metals with relatively low melting points or high-melting-point alloys. It can select a certain area for cladding, and the material consumption is high cost-effective. At the same time, high-speed aiming allows cladding in some hard-to-reach areas, and the process is easy to automate.

High-speed laser cladding machines rely on laser cladding forming technology and have advantages such as process automation, low thermal stress, and small deformation effects. Because people want to extend the service life of aircraft equipment, more complex repair and maintenance processes are needed. Turbine blades, impellers, and rotating air seals are parts that can extend the life of existing structures by updating them. Some of these parts can be repaired by surface hardening, but many other parts require more complex repair processes and are made of difficult-to-process materials. The cladding and repair process of the laser cladding machine can be applied to a wide range of materials without reducing the performance of the base material, saving costs up to 75% or more compared to replacing parts or tools.

Currently Laser cladding machine Its application in the aerospace field is very extensive, and the existence of this equipment can better improve the service life and performance of parts.

Related Information

RELATED INFORMATION

2022-08-26 10:09

2022-08-16 15:13

2022-08-08 10:10

Leave a message

MESSAGE CONSULTATION