07-07

Some knowledge points about laser cladding, told by a hydraulic pillar laser cladding manufacturer

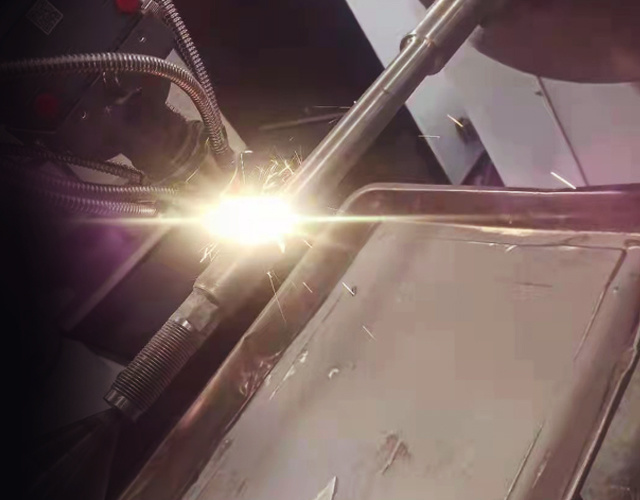

Hydraulic support laser cladding manufacturers believe that laser cladding technology refers to the process of placing selected coating materials on the surface of the substrate to be coated in different filling ways, melting them with laser irradiation and the thin layer on the substrate surface, and rapidly solidifying to form a surface coating with extremely low dilution. It forms a metallurgical bond with the base material, thereby significantly improving the wear resistance, corrosion resistance, heat resistance, oxidation resistance, and electrical properties of the base material surface.

06-27

Laser cladding technology for hydraulic rod laser cladding equipment is also known as laser remanufacturing technology and laser repair technology. Laser cladding technology is a new technology that uses high-density lasers and special laser cladding materials to perform alloy strengthening treatment on various parts. It can significantly improve work efficiency, increase the surface hardness, corrosion resistance, and wear resistance of metal parts, extend the service life of parts, achieve increased production, reduce consumption, and save resources.

06-17

How are the two applications of hydraulic rod laser cladding equipment technology implemented?

The rise of hydraulic rod laser cladding equipment represents a new technology that utilizes high-energy density laser beams to clad materials with special properties onto a substrate material. This process creates a clad layer of alloy that melts and fuses with the substrate, resulting in a completely different composition and properties compared to the substrate.

06-07

Laser cladding technology for hydraulic rod laser cladding equipment is a surface modification technology that adds cladding powder material to the surface of the substrate that needs to be repaired or strengthened. Then, the high energy of the laser is used to form a metallurgical bond between the powder and the substrate, forming a cladding layer with wear resistance, corrosion resistance, oxidation resistance, or electrical characteristics. This achieves basic repair or surface modification and improves the service life of parts.

04-08

What is the coaxial powder laser cladding technology of laser cladding equipment?

Laser cladding technology for laser cladding equipment has many advantages, such as low dilution rate, low heat input, and wide range of materials. It has evolved into various types in the process of industrial application and is widely used in various fields of additive manufacturing, remanufacturing, and surface engineering. According to the material type and the combination form of material and laser beam, typical laser cladding technologies can be divided into coaxial powder laser cladding technology, anti-axial powder laser cladding technology (also known as transverse powder laser cladding technology), high-speed laser cladding technology (also known as ultra-high-speed laser cladding technology), and high-speed wire laser cladding technology.