03-24

What is the principle of the process equipment of high-speed laser cladding equipment?

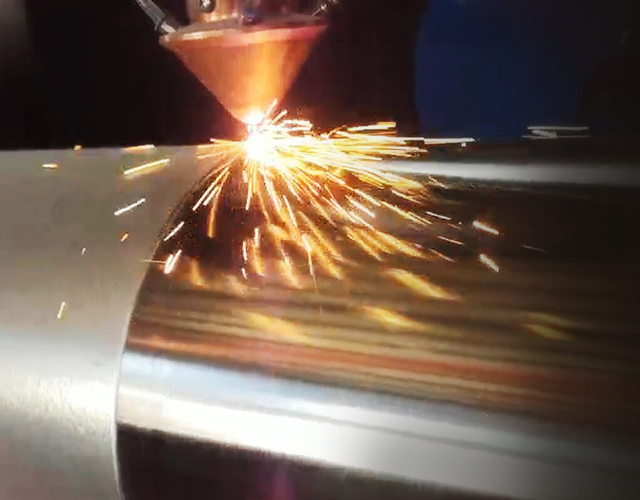

High-speed laser cladding equipment laser cladding is a process that adds external materials to a gas-formed molten pool through laser irradiation with simultaneous or pre-placed materials, and rapidly solidifies the two together to form a cover plate.

03-09

High-speed laser cladding machine manufacturers introduce the selection of laser cladding materials below. Laser cladding materials refer to materials used to form cladding layers. According to their shape, they are divided into alloy powders (powder materials), wire materials, sheet materials, etc. Among them, powder-like cladding materials are widely used. The selection of cladding materials directly affects the service performance and processability of the laser cladding layer.

03-08

High-speed laser cladding machine manufacturers introduce the application of laser cladding technology. Due to the long-term operation of machinery and equipment in harsh environments, it is easy to cause corrosion and wear of parts. Typical easily faulty parts include impellers, large rotor journals, discs, bushings, bearings, etc. Many of these parts are expensive, there are many types of related parts, the shapes are complex, and the operating conditions vary greatly. In addition, large rotors, moving blades, and stationary blades of large thermal power generating units need to be strengthened or repaired.

11-26

Application of high-speed laser cladding machine in aerospace manufacturing

High-speed laser cladding machines can use different filler methods to place coating materials on the surface of the substrate. After laser irradiation, the coating materials melt simultaneously with a thin layer of the substrate itself. After a short period of solidification, a coating with low dilution and good bonding with the substrate material is formed, improving the corrosion resistance, wear resistance, oxidation resistance, heat resistance, and electrical properties of the part.

11-24

Current progress and applications of high-speed laser cladding machines

It is well known that the level of agricultural machinery manufacturing and technology in many regions is still relatively low. Therefore, the safety, reliability, durability, and applicability of the products produced still have a large gap compared to other regions. Especially for key components of agricultural machinery, such as furrow openers, harvester blades, and rotary tiller blades, if these key wear-resistant parts fail, it will greatly increase maintenance costs and affect the efficiency of machinery operation. Therefore, the existence of guide plate laser cladding machines is extremely important.